Choosing between a V6 and an inline-6 engine is a critical decision for automakers and enthusiasts alike. Both offer compelling performance characteristics, but their underlying design philosophies lead to significant differences in smoothness, packaging, manufacturing costs, and modification potential. This article provides a comparative analysis to help you understand which engine type best suits your needs.

Cylinder Arrangement & Balance: A Tale of Two Smoothnesses

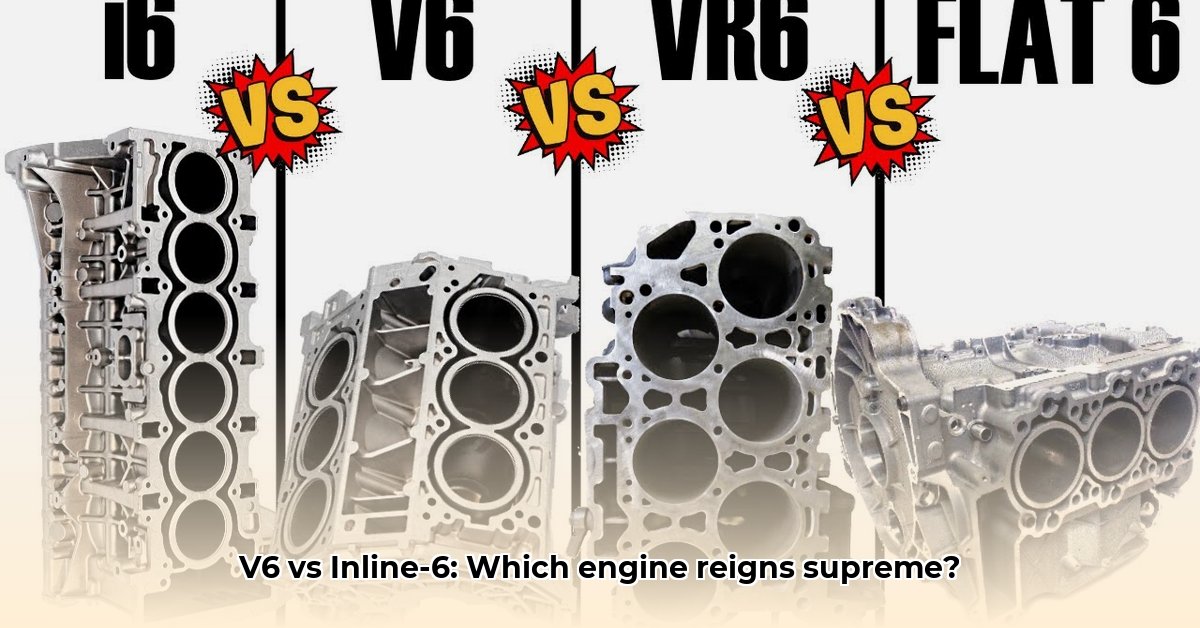

The core difference lies in cylinder arrangement. V6 engines feature two banks of three cylinders arranged in a V-shape (typically 60° or 90°), while inline-6 engines position all six cylinders in a single, straight line. This seemingly minor detail dramatically affects engine balance and smoothness.

Inline-sixes, with their inherent symmetry, possess exceptional inherent balance. This translates to significantly reduced vibrations and a remarkably smooth operation, creating a refined driving experience. V6 engines, while often compact, require counterweights to mitigate inherent imbalances, resulting in less smoothness. While some advanced V6 designs, particularly those with a 120° V-angle, achieve impressive smoothness, they generally do not match the refinement of an inline-six. This difference is akin to comparing a perfectly balanced spinning top versus one experiencing slight wobble.

Size and Packaging: Space Constraints

Space within an engine bay is a significant design constraint. V6s, with their compact, V-shaped layout, are easily integrated into smaller engine compartments, often found in front-wheel-drive vehicles. This adaptability makes them a versatile choice for a broad range of applications.

Inline-six engines present a different challenge, as their longer length requires more longitudinal space. This necessitates different packaging strategies in vehicle design. These engines often find use in rear-wheel-drive or all-wheel-drive vehicles where the longitudinal design fits better, however this may affect other design elements, such as cabin space or trunk size.

Manufacturing Costs: A Production Perspective

Manufacturing costs vary significantly between the two engine types. V6 engines are typically cheaper to produce. Their simpler design and fewer parts require fewer manufacturing steps, leading to cost savings.

Inline-six engines, in contrast, incur higher manufacturing costs. Their more intricate design necessitates more complex machining operations and often higher precision components. This increased complexity directly translates into higher production expenses. Nevertheless, ongoing innovation in manufacturing techniques may narrow this cost gap in the future.

Performance & Efficiency: Power and Economy

Both engine types can deliver impressive performance. V6s often excel at high-revving power delivery, providing a thrilling, punchy experience at higher engine speeds. Inline-sixes, conversely, often generate strong low-end torque, providing a more immediate and powerful feel at lower RPMs.

Fuel efficiency is highly dependent on specific engine design, displacement, and technological advancements. It's inaccurate to declare one type inherently more fuel-efficient than the other. The actual fuel consumption varies widely based on many factors beyond the engine's basic architecture.

Modification Potential: Tuning and Customization

For automotive enthusiasts, modification potential is a key factor. Inline-six engines are often preferred for their relative ease of modification. Their modular design and accessibility make adding performance parts and tuning for increased power comparatively straightforward.

Modifying V6 engines can also yield power gains, but it frequently requires more complex procedures and potentially extensive alterations, compared to the inline-six which is generally easier to customize. This ease of modification makes the inline-six favored by many performance enthusiasts.

Market Analysis and Future Trends: Shifting Tides

Currently, V6 engines hold a dominant market share due to their cost-effectiveness and versatility. However, a noticeable resurgence of interest in inline-six engines is underway, particularly within the luxury and high-performance segments. Several manufacturers are reintroducing these engines, signaling a potential shifting of the market balance.

The rise of electric and hybrid powertrains will inevitably impact both V6 and inline-six engines. Though it’s premature to predict the long-term outcome, many experts foresee a strong niche remaining for inline-six engines, especially in applications where smoothness and refinement are highly valued, such as luxury and performance vehicles.

Actionable Intelligence: Guidance for Stakeholders

Auto Manufacturers: Invest in R&D for hybrid/electric inline-six powertrains, while responding to growing market demand for higher-performance inline-6 engine options.

Engine Designers: Concentrate on optimizing V6 designs for efficiency and smoother operation. Also invest in advanced manufacturing techniques to make inline-six production more cost-effective.

Aftermarket Companies: Expand product offerings to cater to both V6 and inline-six engine modifications. Consider niche markets, such as classic car restoration.

Consumers: Base engine-type selection on individual vehicle priorities – prioritizing space efficiency, performance characteristics, and budget.

Conclusion: The Verdict

Ultimately, the choice between a V6 and an inline-six engine depends entirely on specific application requirements and priorities. Both offer unique advantages and disadvantages, with advancements in technology poised to impact their respective market positions and future development. A careful consideration of the factors discussed above is integral to making an informed decision.